Custom Medical Sensor Design for Their Environment: 2 Checklists

Maybe you’ve had a basic four-door sedan. It works well for everyday driving, no surprises there. But put it somewhere it wasn’t built to go – like a snowy back road or uneven trail – and it’s going to struggle.

Medical sensor design isn’t all that different.

A healthcare sensor might check all the boxes in testing, but if the environment it ends up in isn’t part of the design process, things can go sideways. Heat, pressure, fluids, and other everyday stressors all play a part in how well a sensor holds up.

That’s why it helps to think through where and how your sensor will actually be used. The two checklists below walk through the environmental factors and design steps that shape a more reliable sensor – one that’s ready for the real world.

Checklist 1: Environmental Factors to Weigh in Medical Sensor Design

In patient care, sensors face some of the hardest environments to operate in.

While medical sensors aren’t in dangerous or incredibly unique situations (e.g. monitoring temperature inside a nuclear reactor) they do face elements that can impede accuracy or require real-time adjustment. What's more, in some cases a sensor’s performance – as well as the medical device it’s installed in – can mean the difference between life and death.

Ultimately, designing a medical sensor that is accurate and robust comes down to:

- Recognizing the myriad environmental factors it will face

- Preserving precision for the device's entire useful life

In working with a sensor manufacturer, you’ll need to assess and plan for the environmental elements your sensor will encounter. Your checklist of environmental factors to discuss should include:

- Temperature: What temperature range will the sensor operate in? How frequently will temperatures change? How drastic will temperature changes be?

- Pressure: How intense is the pressure in the environment the sensor will operate in? Will external pressures change? What degree of accuracy are pressure measurements needed within?

- Chemicals & Fluids: While in use, what chemicals or fluids will the sensor be exposed to? In the case of reusable sensors, what cleaners are used to sterilize the device or equipment it's installed in?

- Electrical Interference & Noise: Will the device be exposed to electrical interference? If so, how severe is it and what kind of compensation should the sensor have for accuracy when this occurs?

- Physical Stress: Will the device be subject to shock or vibration while installed in a medical device? How intense will these mechanical stresses be, and how can they best be mitigated?

- Humidity: Will the sensor be exposed to humidity? If so, in what humidity ranges will the sensor operate? Will external conditions change frequently, or will the environment remain fairly consistent?

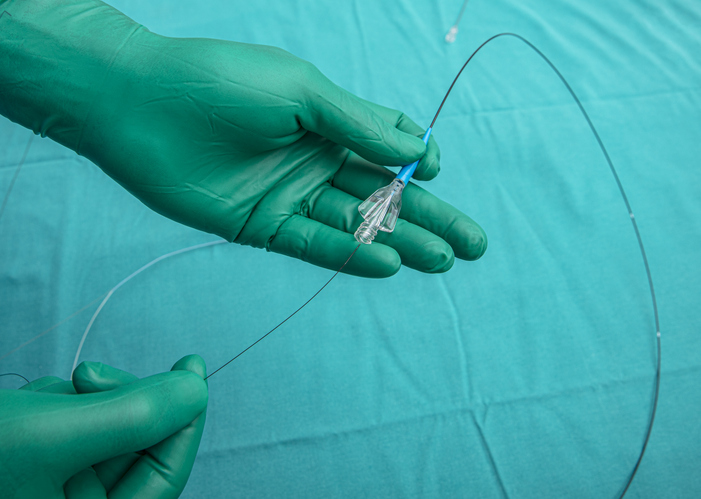

- Space Constraints: This is two-fold and we'll use a catheter as an example: How big a space will the medical sensor be operating in (e.g., is the sensor inside a catheter that will be fed into an artery)? Does the medical device have limited space for the sensor itself (i.e., how small does the sensor need to be to fit inside a catheter)? Does the sensor need to be miniaturized?

Matching Precision with Sensor Lifespan

In an ideal scenario, a sensor would never be impacted by environmental factors and its useful life would be limitless.

However, no device is designed to last forever. In fact, sometimes devices – including certain medical body sensors – are made to be thrown out after a single use.

Environmental factors do more than contribute to a sensor's expiration date – they also can impact how the sensor functions during its useful life. Though reliability and accuracy are often discussed as important considerations for sensor design (and they are), there's one overarching factor that's more encompassing and crucial: precision.

Environmental factors do more than contribute to a sensor's expiration date – they also can impact how the sensor functions during its useful life. Though reliability and accuracy are often discussed as important considerations for sensor design (and they are), there's one overarching factor that's more encompassing and crucial: precision.

The performance of an OEM medical device or even those providing patient care relies heavily on the data provided.

In most cases, it comes directly from a sensor. And without careful design, even the smallest fluctuations in environmental variables can ultimately limit the precision of sensor readings. Thus, aligning medical sensor precision with lifespan requires finding the delicate balance between accuracy, durability, length of application, and even expense.

High-precision sensors may offer more accurate data, but they may also be more expensive and have a shorter lifespan due to the complexity of their design. On the other hand, low-precision sensors may be more affordable and have a longer lifespan, but their data may be less reliable.

Checklist 2: The Right Design for the Right Tool

Finding a healthcare sensor that's up to meeting the rigors of demand isn't always as simple as contacting its manufacturer and buying their "off-the-shelf" products.

Most of the time, this never happens. At least it shouldn't.

As medical care is complex and often requires unique solutions, the sensor technology involved in it needs to match. In other words,every medical device and patient care application is different and requires tailored solutions.

Custom-designed sensors built for a specific device or area of care help protect lifespan and precision from being affected by environmental factors too soon.

When approaching medical sensor design for specific environmental demands, a sensor manufacturer goes through a systematic process to support the device’s performance, longevity, and reliability. Their checklist should include:

- Defining Environmental Requirements: An important first step is to clearly define the environmental requirements the sensor needs to withstand – be it temperature, pressure, or any other factor. This also includes materials the sensor is in direct contact with within its housing. For instance, some sensors are coated in a protective gel, which can also put a level of stress on the sensor and its performance. Understanding what the sensor's up against while in use determines most every other design decision for the device.

- Material Selection: Based on the defined environmental requirements, the manufacturer evaluates different materials to identify those that can withstand specified conditions or even repeated sterilizations.

- Material Testing & Validation: Once potential materials are identified, the manufacturer conducts material testing and validation to ensure their suitability for the intended application. This may involve subjecting the materials to environmental stressors such as temperature cycling, humidity exposure, or mechanical stress to evaluate its performance and stability under specific environmental conditions.

- Shape, Size, & Housing: The manufacturer incorporates design features that protect the sensor's ability to withstand environmental demands. This may include elements such as protective enclosures, sealing mechanisms, insulation layers, and shock-absorbing structures. The design should also consider ease of cleaning, sterilization, and maintenance for reusable devices.

- Device Validation & Testing: Custom sensors go through thorough validation and testing to confirm they match the outlined environmental conditions. This includes performance testing under simulated environmental conditions, such as temperature and humidity chambers, exposure to chemicals, and mechanical stress testing. The sensors are evaluated for accuracy, reliability, and durability to confirm they can withstand the intended environment.

- Compliance and Certification: Depending on the application and regulatory needs, the manufacturer aligns the custom sensor with applicable standards. This may include obtaining approvals from governing bodies to confirm the sensor meets expected performance and safety guidelines.

Environment-first thinking matters in Medical sensor design

Designing medical sensors without considering their environment can lead to performance issues when it matters most. Exposure to heat, pressure, cleaning agents, or electrical interference can impact how long a sensor lasts – or how accurately it reads.

Working those details into the early stages of medical sensor design helps create devices that perform reliably in the real world. That means better data, stronger outcomes, and more confidence in critical care situations.

If you're planning a device for high-demand environments, our engineers can help you take the next step.

Ready for the demands ahead?

If your sensor need to perform under pressure our team can help design for it.

This article was originally published in June 2023 and was recently updated to reflect current industry trends.

![[Timeline] Creating Sensor Technology in Healthcare](https://blog.amphenol-sensors.com/hubfs/Sensor%20technology%20in%20healthcare.jpg)