EV Battery Pack Sensors: What Your Cell Connection System Needs

The heart of an electric vehicle (EV) is its battery pack, and the module cell connection system is the infrastructure that connects the individual cells to the high-voltage output of the pack.

Without either functioning properly, a battery-powered vehicle may experience a host of issues – from poor performance to an outright failure.

Inside the pack, the EV battery cell connection system combines individual cells in parallel and series configuration to create both energy and power for the pack, as well as providing critical sensor data to the Battery Management System (BMS) to control the pack functions.

Sensors That Ensure EV Battery Pack Safety, Performance & Longevity

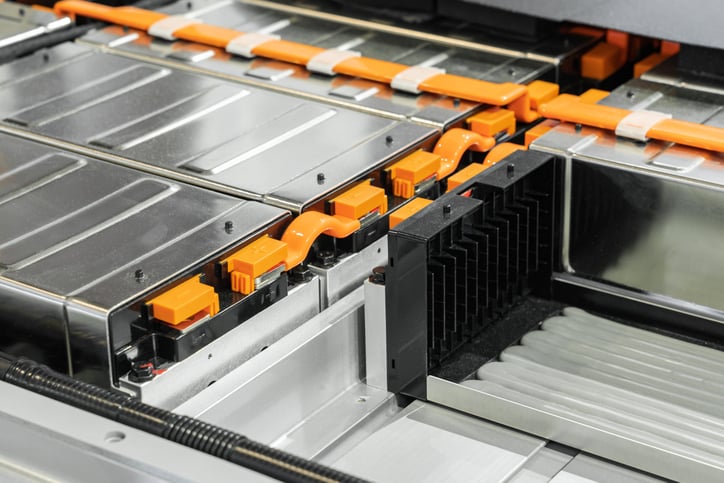

In addition to providing the busbars that connect the cells and allow current to flow between the individual cells, the cell connection system incorporates temperature sensors for measuring the battery cell and busbar temperatures, which are critical for controlling cell temperature within its optimum performance range for optimal performance and life. Lithium-ion cells perform best between temperatures of 10℃ and 45℃, and the battery thermal management system can provide both heat and cooling to the cells, but must have highly accurate temperature measurements to properly maintain the cells' temperature during driving and while at the charging station.

EV battery packs experience greater thermal and electrical stress than traditional Internal Combustion Engine battery systems. In a typical Electric Vehicle, the battery pack may experience thousands of charge and discharge cycles throughout its life. The pack Battery Management System monitors the voltage, current, and temperature of cells.

Sensors that should be considered within the EV vehicle components and battery pack design:

-

Temperature

-

Voltage & current

-

Gas Detection

-

Water intrusion / Coolant breach

1. Temperature

Temperature sensors are critical for electric vehicle battery and cell connection system applications. Put simply, both parts of an EV require constant thermal management for optimal performance and vehicle occupant safety.

The need for temperature monitoring for electric vehicle batteries is two-fold:

-

When in use – be it powering the vehicle or acting as a source for electricity – batteries give off heat. If left unchecked, high temperatures will damage cells, causing them to degrade and lose charging ability or capacity (SOH and SOC). In extreme cases, the cells decompose, starting a chain reaction of thermal runaway. In addition, in extreme cold conditions, charging cells can result in lithium dendrite growth, which can cause an internal short circuit in the cell, potentially leading to thermal runaway.

-

If not being driven (think: recharging), temperature sensors allow the BMS to control the thermal management system to keep the battery in the optimum temperature range to maintain long life. In addition, if there are any issues with a battery cell, temperature sensors can provide critical safety data to the BMS, which can immediately notify the vehicle’s owner if the pack is in an unsafe state.

Like the battery itself, an EV’s cell connection system is not immune to the effects of excessive heat. EV vehicle battery components, such as a busbar, get hot when in use. The part of the battery through which power flows and is connected to each battery cell, heat from the cell connection system can transfer to each battery cell. Busbar design for proper thermal management is an essential element of engineering robust battery systems.

2. Voltage & Current

Maintaining an electric vehicle’s power is a balancing act of sorts.

A cell’s State of Charge is a calculated metric that describes the amount of charge it can hold. 100% SOC is a fully charged cell, and a 20% SOC cell has very little energy left. If a lithium-ion cell’s state of charge drops below 20%, the copper in the current collector can go into solution in the electrolyte, which can cause a short circuit and fire. If a cell is overcharged beyond 100% SOC, it can also undergo thermal runaway. To calculate SOC, highly accurate voltage, current, and temperature measurements are necessary. When designing the circuits that provide the signals to voltage and current sensors mounted on the BMS, it is essential to ensure there is minimal resistance in the sense circuits, regardless of the cell's location and the sense lead length. Of the hundreds of sensor connections between bus locations and the BMS, every one must be appropriately designed and manufactured to accommodate the thermal, intercalation, and pack stresses as batteries swell and shrink with the effects of charging and discharging. To accommodate this, sense circuits must be flexible without losing function and must be securely soldered to the contact points on the busbars.

With hundreds or thousands of individual cells providing power to the vehicle, each can have different states of health (SOH) after prolonged use. SOH is another calculated metric that approximates the remaining useful life in a cell. As with SOC, the calculation is very dependent upon reliable voltage, current, and voltage measurements over time.

In the case of EV batteries, they are generally considered to be no longer useful when their SOH value falls much below 80%.The batteries within a module act as a team, where the module's performance is governed by the weakest cell in the string. To manage this, the BMS must perform cell balancing to make sure that individual cells are neither overcharged nor drop below specific SOC values to keep the SOH as high as possible across all the cells. As even a single cell performing poorly can degrade the performance of the module and hence the pack, it is critical to obtain the best available information from the embedded sensors.

New technologies, such as impedance spectroscopy, are also emerging as techniques to obtain the best information available on lithium-ion battery cell health. As the new control electronics for this technique are being developed, the cell connection systems will grow organically to include more of this sensor intelligence close to the cells.

The balance between the cells comprising an electric vehicle’s battery maintains:

- Charging capacity & charge rates

- Vehicle range

- Battery health & life

3. Gas

One of the most damaging – and dangerous – events in a battery-powered vehicle is thermal runaway. A process started by overheating, thermal runaway, moves quickly through a battery pack as battery cells deteriorate.

Next to abnormally high battery pack temperatures, a sure sign that thermal runaway has started is the presence of vented flammable gases, including:

- Hydrogen

- Volatile hydrocarbons

- Carbon monoxide & dioxide

- Dimethyl carbonate

- Hydrogen fluoride

- Acetonitrile

The best time to stop thermal runaway from overtaking an EV battery system is the second a single cell starts to vent the flammable gases. The sooner you’re able to stop the process, the less damage it causes and the danger it poses. New cell connection system designs can incorporate these gas sensor technologies directly onto their surface, providing the fastest response to a failed cell.

With gas sensors embedded close to the cells, early detection for thermal runaway is built into the part of an electric vehicle closest to the potential failure point.

4. Water Intrusion & Coolant Leak Detection

Like any vehicle, even a small leak can be a big problem for an EV. In an electric vehicle, coolant and humidity-based condensation, and water intrusion within the battery pack’s case are particularly problematic for two main reasons:

-

The presence of water or condensation from humidity can cause a short circuit. For an EV, a short circuit can have a minimal effect, such as a blown fuse or the vehicle entering safe mode, or cause much bigger issues, such as system failures or thermal runaway. Even in small amounts, water can also cause corrosion issues in critical electronics, potentially leading to failure.

-

Water/glycol-based coolants are typically used in the cod plate or cooling passages within EV battery packs to extract heat from the cells. If the connections or cooling lines inside a battery pack fail, coolant breaches into the battery space and places conductive fluid in areas that can create short circuits. In addition to making the opportunity for shorting the control or high voltage electronics, water from either condensation or coolant can hydrolyze when exposed to the current conductors in the pack, generating hydrogen and oxygen, which can also create issues. For this reason, it is also critical to protect circuit traces in the cell connection system from moisture and corrosion.

Regardless of the source, fluids inside an EV battery pack require immediate attention to preserve the functionality of the power unit.

EV Battery System Sensor FAQs

How do the Sensors Discussed Impact an EV’s Overall Efficiency Under Different Climate Conditions? In varying climatic conditions, these sensors help adjust the battery's operating state to maintain optimal performance and longevity, ensuring that the battery functions efficiently even under extreme temperatures. Can the Sensor Technologies Mentioned Above be Adapted to Hybrid Electric Vehicles? In short, yes. Advanced sensors are versatile in monitoring battery health, which is fundamental to both types of vehicles, thus facilitating improved management and operational efficiency of hybrid power systems as well. Are There Any Future Trends or Upcoming Advancements for EV Sensor Technology That Would Enhance Battery System Management Systems? Another easy one – yes. One trend to keep an eye on is advanced sensors with integrated IoT technology to provide more sophisticated data analytics to predict battery needs and maintenance. It’s already poised to have a place for fast charging. |

Optimizing EV Battery Pack & Cell Connection System Cases With Advanced Sensors

The defining components of an electric vehicle, a battery pack, and its cell connection system, require constant sensing of many critical parameters for robust life.

With battery sensor technology strategically placed throughout the cell connection system, maintaining battery EV health and performance happens reliably and in real-time.

Designing Sensors and Cell Connection Systems for Your Battery

Speak with one of our engineers about the Amphenol sensors available for your entire electric vehicle’s design.