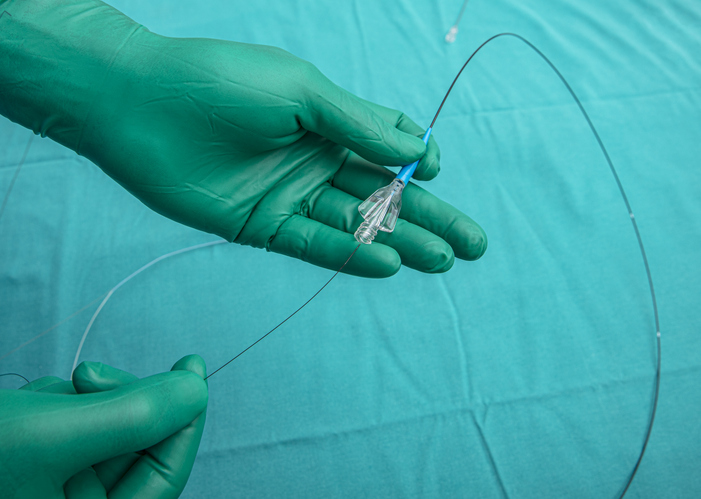

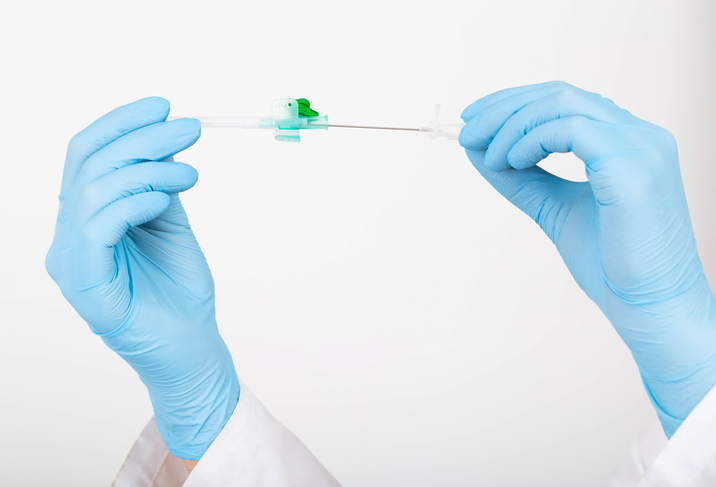

How the Application of Sensors in Healthcare Improves Catheter Design

Advancements in medical technology continue to reshape how care is delivered, with connected devices playing a growing part in clinical decision-making. The application of sensors in healthcare has expanded what medical devices can measure, monitor, and report in real time.

![[Timeline] Creating Sensor Technology in Healthcare](https://blog.amphenol-sensors.com/hubfs/Sensor%20technology%20in%20healthcare.jpg)