EU Battery Regulation Overview for EV Manufacturers

There’s no arguing that electric vehicles are changing the world. Not only are they reducing our dependence on fossil fuels, but they're also making clean energy more accessible.

Outside of transportation, however, they're having an even bigger impact. Beyond lower emissions and charging stations popping up in the parking lots of major retailers, EVs are forcing governments and corporations to rethink how business is conducted.

The EU Battery Regulation and its predecessor, the EU Battery Directive, are two of the most impactful laws shaping the future of electric vehicle production in Europe.

Both laws compel EV manufacturers to meet some of the strictest regulations for sourcing and environmental impact. In fact, compliance goes beyond a manufacturer's four walls – meeting the directives' standards means working with vendors and suppliers of parts or utilities that also adhere to the EU regulations.

For EV manufacturers, both standards means one thing: If you're looking to sell electric vehicles in Europe, you need to comply with the EU Battery Directive and start taking steps toward meeting the Regulation's future provisions.

A Look at the EU Battery Directive

The European Union Battery Directive, or EUBD, is an important legal framework introduced in 2006 to regulate the production and handling of batteries within the European Union. It aims to protect human health and the environment by ensuring the safe management of batteries throughout their entire life cycle – from production through disposal.

The EUBD applies to all types of primary and secondary (rechargeable) batteries, including those used in electric vehicles.

Key Updates to the EU Battery Directive Since 2019

In 2019, the EUBD underwent a major overhaul with several changes designed to improve upon its effectiveness.

The updated law aims to reduce the environmental burden of battery production, including increased restrictions on heavy metals such as mercury, lead, and cadmium. In addition, the revised EUBD requires manufacturers to use "best available techniques" (BAT) when managing end-of-life batteries. This includes measures such as collecting used batteries for recycling or recovery and implementing strict standards for waste storage and disposal.

Another important update is that all products containing batteries are now required to be labeled with a universally unique identifier (UUID) that can be traced back to the manufacturer. This helps prevent counterfeited or unsafe products from entering the market by allowing authorities to quickly track down their source if needed.

To further promote sustainability, the revised regulations now promotes energy efficiency labeling for electric vehicles. This rating system allows consumers to easily compare different models based on their energy efficiency performance. The ratings are determined by simulations conducted in accordance with EU standards and reflect various elements such as powertrain design and driving range.

The 2019 update also impacts primary and secondary (rechargeable) batteries; they now also cover portable fuel cell systems used in consumer applications such as laptop computers or mobile phones. Fuel cells are known for producing electricity more efficiently than traditional batteries; however, they still generate hazardous waste which needs to be managed properly according to EU guidelines.

What Is the EU Battery Regulation?

During this decade, the EU Battery Regulation – which is part of the EU Green Deal – will replace the Directive and take green laws for batteries to the next level. Compared to the EU Battery Directive, the Battery Regulation will be more wide-reaching and impactful.

Like the directive, the Battery Regulation impacts the use, production, distribution, and disposal of batteries within European countries. This legislation seeks to improve battery sustainability and reduce its environmental impact. The goal is to ensure that all batteries used, sold, and produced in the EU are safe, efficient, and sustainable.

Similar to the Battery Directive, the main goals of the regulation are to:

-

Reduce the environmental impact of battery manufacturing and use: Initiatives to improve recycling rates, reduce waste, limit exposure to toxic chemicals during production, and promote sustainable practices throughout the battery life cycle.

-

Ensure that batteries meet strict safety standards for consumers and workers: Includes regulations to prevent thermal runaway, reduce risks of fire and explosions, and promote safe handling practices.

-

Improve battery manufacturing efficiency and sustainability: Regulations that require companies to use sustainable materials in the production process, as well as measures to improve energy efficiency.

-

Enhanced traceability & battery passports. All manufacturers must issue a "passport" for every battery they produce. This passport must contain information related to the components, quality of materials used, procedures that have been applied during production and how to dispose of batteries.

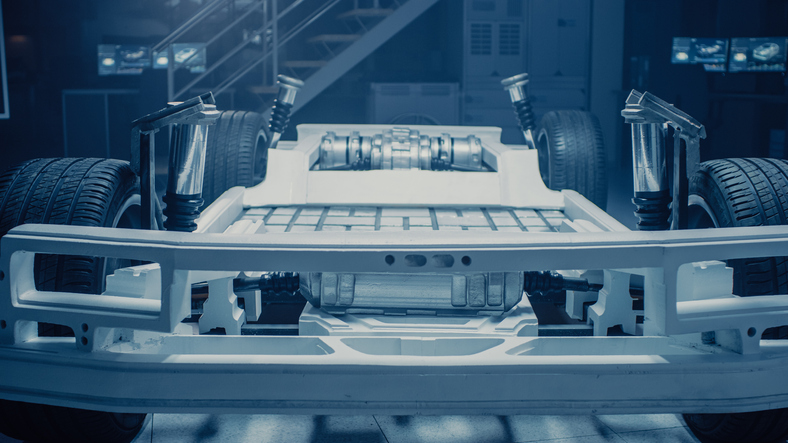

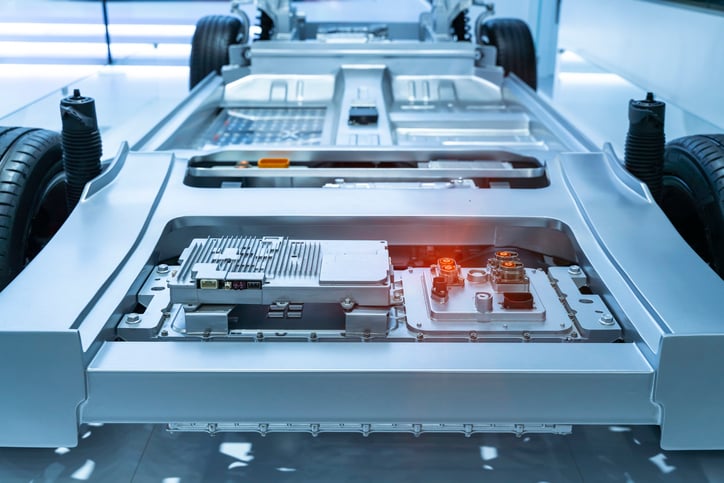

Learn more about an EV’s battery thermal management system:

How Does the EU Battery Regulation Impact EV Battery Production?

Overall, the Battery Regulation is an important step towards improving the sustainability of batteries and reducing their environmental impact. By prioritizing safe manufacturing practices, promoting sustainable materials, and setting high standards for battery performance, this legislation helps ensure EV batteries are a safer, more efficient, and more sustainable option for consumers and businesses alike.

2025 and Beyond: EU Battery Regulation Timeline

With the regulation now in place and the old directive being phased out, it’s important for EV manufacturers and other stakeholders to stay up-to-date on the latest developments.

But more than that, they should already be adapting to what they can while taking steps to meet these new laws and standards. To be blunt: It's comply or die. An EV manufacturer cannot afford to fall behind in these regulations if they plan to do business in the third-largest economy in the world.

Here’s a quick look at the key regulatory milestones:

-

2023: EU Battery Regulation officially enacted

-

2024: Carbon footprint declaration required for all battery types

-

2025: Battery Passport implementation deadline

-

2026: Carbon footprint performance report due

-

2027: Mandatory reporting on recycled content & carbon footprint thresholds enforced

-

2028: Recycled content targets re-evaluated

-

2030: Recycled content targets enforced across all EV batteries

Sensor Technology & Compliance: A Key Piece of Battery Regulation

EV sensors may be small, but their role in meeting EU Battery Regulation requirements is anything but.

As the regulation comes into effect, EV sensor makers will also need to prioritize safe manufacturing practices, use sustainable materials, and meet high standards for performance.

How Sensors Used in Electric Vehicles Support Battery Compliance

By including sensor technology capable of monitoring and collecting data on battery components, energy efficiency, and recycling rates, your battery can remain ahead of the curve.

For example, battery temperature sensors are essential in ensuring that batteries aren't overheating and an EV is meeting safety guidelines. Similarly, current sensors can measure charging currents and battery discharge rate to maximize longevity and energy efficiency. This helps EV makers meet 2025 Carbon Footprint Declaration requirements as well as threshold targets set for recycled content use in 2027.

By keeping pace with new regulations while utilizing innovative sensing technology, EV sensor manufacturers have a key role to play in helping EV makers comply with EU legislation. Through collaboration between sensor manufacturers and EV producers, both parties can take advantage of an ever-evolving industry landscape while ensuring customer safety and sustainability along the way.

Battery Directive vs. Regulation: FAQs

How have EV manufacturers already adjusted to the EU Battery Directive? EV manufacturers are enhancing the sustainability of their battery production processes. This includes increasing the recyclability of batteries, using more environmentally friendly materials, and improving battery life span through advanced technology. How do EU regulations compare with similar battery regulations in other regions? The EU Battery Directive is generally more stringent than similar regulations in the U.S. or Asia, especially concerning the recycling and lifecycle management of batteries. The directive includes higher standards for the collection, recycling efficiency, and reuse of battery components. Remember, the EU's regulation was the first major law of its kind. What additional changes should we expect in future revisions? Future revisions of the regulation are likely to impose stricter controls on the environmental impact of battery production. This may include tighter limits on emissions and resource usage during manufacturing, as well as stricter regulations on the disposal and recycling of battery materials. |

The Global Impact of EU Battery Laws on EV Manufacturers

The EU Battery Directive and EU Battery Regulation are already reshaping the EV industry and market. Not only will compliance with both regulations change how business is done in Europe, but also the world over.

Those who fail to meet these standards will have a tough time competing.

Getting Ahead of EU Battery Compliance With the Right Tools

Meeting these regulations doesn't have to be scary. Prepare by using sustainable materials and improving energy efficiency. In addition, your sensor manufacturers can play an important role in helping you comply with regulatory requirements while maintaining a competitive edge.

Talk to one of our EV sensor engineers today to explore a solution for compliant product design: