Supply Chain Vulnerabilities From the Chips Shortage in the Automotive Industry

For nearly three years, the global supply chain for practically anything has left a lot to be desired.

For nearly three years, the global supply chain for practically anything has left a lot to be desired.

Ask any manufacturer in any industry what issue has been one of the biggest challenges since 2020 and most will say the same thing: supply chain management.

As we all found out during the onset of this decade (the COVID years), supply chains are a fragile thing.

But even without a pandemic, supply chains can make or break a production schedule.

Unfortunately, even in the best of times, there will always be some sort of supply chain challenge to overcome.

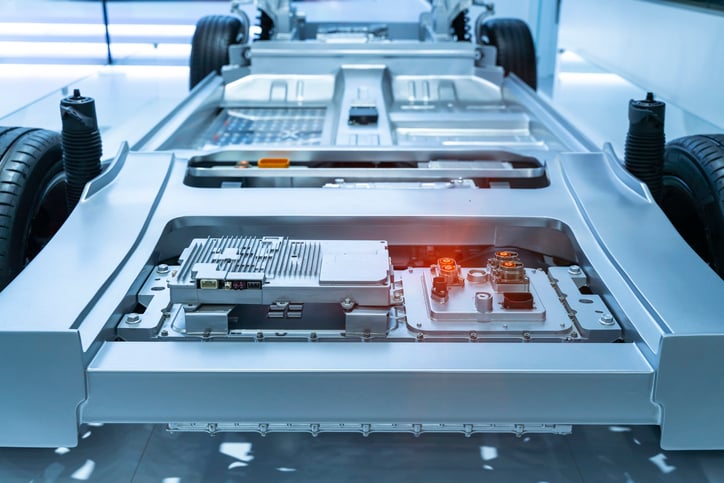

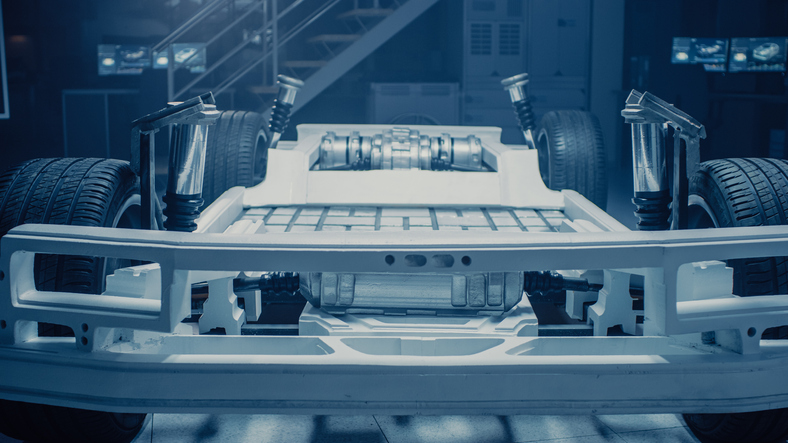

There’s no arguing that electric vehicles are changing the world. Not only are they reducing our dependence on fossil fuels, but they're also making clean energy more accessible.

Outside of transportation, however, they're having an even bigger impact. Beyond lower emissions and charging stations popping up in the parking lots of major retailers, EVs are forcing governments and corporations to rethink how business is conducted.

The EU Battery Regulation and its predecessor, the EU Battery Directive, are two of the most impactful laws shaping the future of electric vehicle production in Europe.

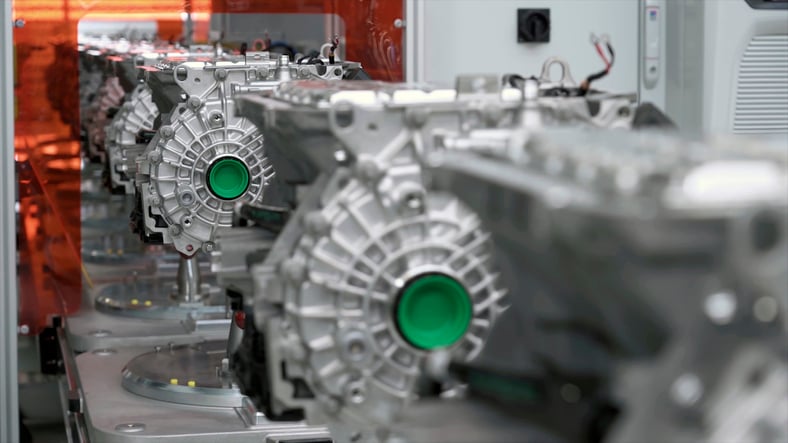

In the history of automotive manufacturing, complete in-house construction of vehicles has been a rarity – especially at the mass-production level.

Put simply, it’s near impossible to build a vehicle – even electric – without incorporating parts from external sources into their builds.

In any manufacturing operation, what often derails production schedules?

Electric cars are getting all the attention in the transportation industry.

It’s one of those worst-case scenarios you hope never happens at your electric vehicle (EV) auto plant.

In some relationships, there's a certain level of expectation for deliverables.

Not too long ago, there were two front-runners in the race for an alternate fuel source for vehicles: hydrogen and electricity.